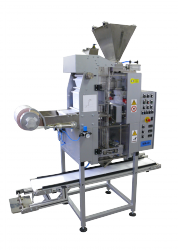

ABM D series

ABM D series are simple and reliable multi-tube packaging machines suitable for packing of various loose (sugar, salt, coffee, spices etc.) and liquid goods (ketchup, olive oil etc.) into stickpacks or flat bags. According to the packed product the packaging machine is equipped with suitable dosing equipment. Bags are made from an endless roll of heat sealable packing material. The foil is cut into individual narrow strips according to the number of tubes (except one-lane packaging machine), all strips are sealed lengthwise and make sleeves. This sleeve is sealed by a cross jaw and a precise dose of packed goods is filled through a tube. Pair of cross jaws seals it transversely and the bags are cut off by integrated blade, bags fall onto an exit conveyor that transports the bags for further handling (cartoning station, carton box, completion etc.). All parts that come into contact with goods of food character are made of stainless steel AISI 304 (upon a special request also in AISI 316L).This series is popular for it favourable price, was developed special for sugar packing and is also offered at a bargain price as a set including packaging machine, dosing equipment, exit conveyor and spare parts, is suitable for production with small batches. The packaging machine is possible to combine with other optional accessories.

| Maximal foil width: | 220 mm |

|---|---|

| Bag measurements: | width 10-48,5 mm, adjustable length 50-130 mm |

| Number of tubes: | 1-8 |

| Maximal output: | 50 cycles/min. (depending on packed product), up to 400 bags/min. |

| Bag type: | stickpack, flat, flat boiling – 3 sides sealed |

| Control systems: | FESTO |

| Drive: | electropneumatical |

| Weight: | 300 kg with dosing equipment |

| Cross seal: | linear grooving, diamond design |

| Type of packed goods: | loose (powder, granules), liquid |

| 3D: | ABM 2D.jpg |

| Technical drawing: | ABM 5D+slide doser-technical drawing.jpg Note: measurements may vary |

| Product sheet: | ABM_D_FINAL.pdf |

| Recommended foil type: | 40-60 g/m2 paper + 12-20 g/m2 PE |